|

The 3212 is a standard servo that has been built by SpringRC specifically

for continuous rotation (up to 60 RPM at 4.8 V), and it produces a

lot of torque (13 kg-cm at 4.8 V). It features two ball bearings on

the output shaft for reduced friction, and it offers easy access to

the rest-point adjustment potentiometer. Essentially, it is a gear

motor that can be controlled by an RC servo controller. It is not

normally used as an actuator, as there is no way of commanding it

to move to a particular position, as a standard RC servo does.

The 3212 continuous rotation servo converts RC servo position pulses

into continuous rotation speed. The default rest point is 1.5 ms,

but this can be adjusted by using a small slotted screwdriver to turn

the middle-point positioner (see the Mechanical Drawing). Pulse widths

above the rest point result in counterclockwise rotation, with speed

increasing as the pulse width increases; pulse widths below the rest

point result in clockwise rotation, with speed increasing as the pulse

width decreases.

Normal servos can be adapted to continuous rotation use, but the problem

is that the range of positions that result in the motor being stopped

or operating at less than maximum speed is very narrow. Continuous

rotation servos, depending on the position commanded, can go forward

or reverse at different speeds. With an adapted continuous rotation

servo, the position range for the different speeds is very narrow,

making it difficult to produce a specific speed.

These dedicated continuous rotation servos are superior because they

have a very wide ˇ§deadbandˇ¨ so you can be sure the motor is stopped

when you command it, and the position range for forward or reverse

motion is very wide, giving lots of speed resolution.

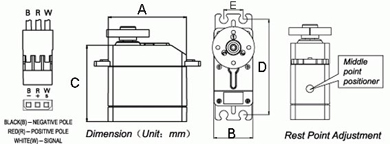

Accessories Bag:

Mechanical Drawing:

| A |

B |

C |

D |

E |

| 42.0mm |

20.5mm |

39.5mm |

49.0 |

10.0mm |

Warning

|

RC servos are hobbyist remote control servos typically

used in radio-controlled models, where they provide actuation

for various mechanical systems such as the steering of a car,

the flaps on a plane, or the rudder of a boat. These servos are

not industrial grade and are not recommended for continuous heavy

use. |

Controllers:

This Servo can be used with the following Phidget

motor controllers:

1066 - PhidgetAdvancedServo 1-Motor

1061 - PhidgetAdvancedServo 8-Motor

The 1061 will produce a little more torque than the 1066. When connecting

the servo motor to the motor controller, make sure that the cable wires

line up with the proper colors as marked on the conroller board.

|